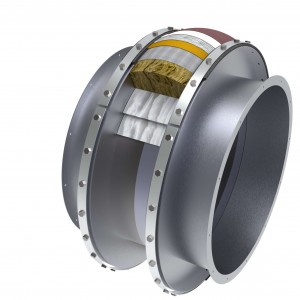

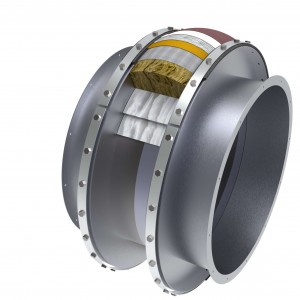

Fabric Expansion Joint

Product Detail Fabric Expansion Joint

Fabric fittings are mainly used to repel thermal expansion and contraction in the duct path carrying gaseous fluids such as hot air or combustion gases. With the advancement of science and technology of processing refractory flexible materials and the introduction of new products, today refractory fabric joints are widely used in most industrial centers such as power plants, steel industries, cement factories, oil and gas refineries, petrochemical centers, Chemical industries, wood and paper industries, recycling factories and so on. These types of connections are used to absorb movement and vibration in transmission lines with a maximum pressure of 0.1 bar and in the temperature range of 1100 °C.

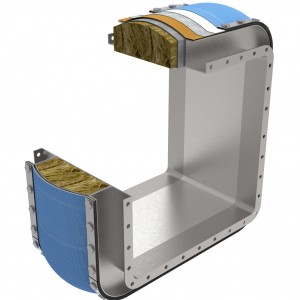

Fabric joints usually consist of one or more layers of refractory fabric. The material, thickness, number and composition of the layers are selected according to the working conditions of the joints. The first layers are usually woven refractory fabrics and stainless-steel nets. These layers are used to increase mechanical strength and also as the first heat shield. The next layers are flexible insulators, which are very resistant to vibration and movement due to the use of long, thin and intertwined fibers. Insulation layers are usually used at temperatures above 300 °C. Also, the material, number and thickness of insulation depends on the temperature of the passing fluid. If the passage fluid contains corrosive chemical compounds, a thin layer of PTFE or a refractory cloth with Teflon coating is used as a chemical shield.

Advantages

- Ability to repel many movements simultaneously and in all directions

- Compensate for misalignment of ducts

- Reduction of noise pollution and reduce heat loss

- Very low spring coefficient compared to other joints

- Elimination of vibrations due to the operation of oscillating equipment such as fans and compressors, etc.

- Reduction of fixed points or supports in the duct path

- Less weight compared to other types of connections

- High resistance to chemical corrosion

- Ease of handling, storage, installation, repair and replacement, resulting in reduced downtime and repairs

Usage

- Transfer of hot gases in flexible sections

- Gas outlet path in gas turbines

- Types of ducts used in oil, gas and petrochemical industries

- Cement industries

The Main Parameters in The Design of Fabric Fittings

- Type of fluid and its corrosion rate

- Fluid temperature

- Work pressure

- The number of movements requested from the connection

- Type and number of abrasive particles in the fluid

- Fluid velocity

- Environmental conditions of the fabric connection installation site